IEC60900:2012 Live Working Tests performed on all Boddingtons Electrical Insulated Tools.

As part of the IEC 60900 Live Working - Hand Tool Compliance , did you know every insulated tool goes through these stages at our premises .

- Visual check

- The hand tool in particular the insulation shall be visually checked and shall be free from external defects

- Dimensional check

- Impact test

- Ambient temperature impact test

- Low temperature impact test

- Dielectric test

- Indentation test

- Test for adhesion of the insulating material coating of insulated hand tools

- Test for adhesion of exposed conductive parts at the working head of hybrid hand tools

- Mechanical tests

- Durability of marking

- Flame retardancy test

The insulating material applied on hand tools shall adhere securely to the conductive part from - 20°C to +70°C

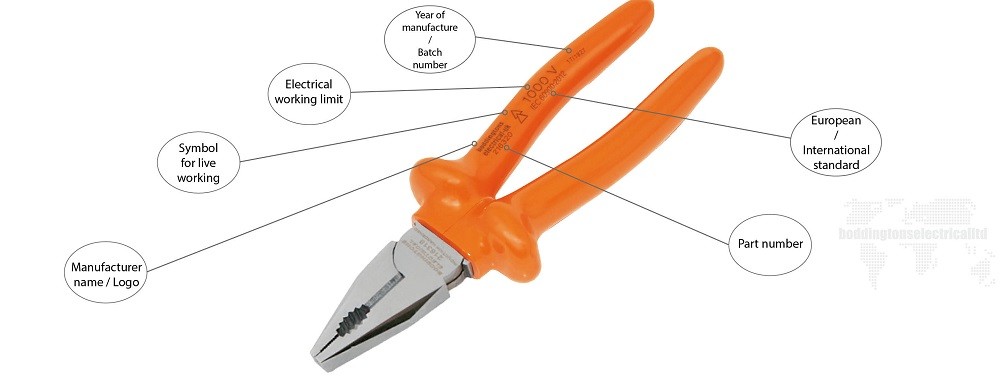

before each tool is clearly marked with

- model/type reference

- year of manufacturer

- symbol of IEC 604517-5216: 2002-10 - suitable for live working double triangle

- indication 1 000 V (i.e. the electrical working limit for alternating current), immediately adjacent to the double triangle symbol

All hand tools that have failed the type tests shall be either destroyed or rendered unsuitable for use in live working.